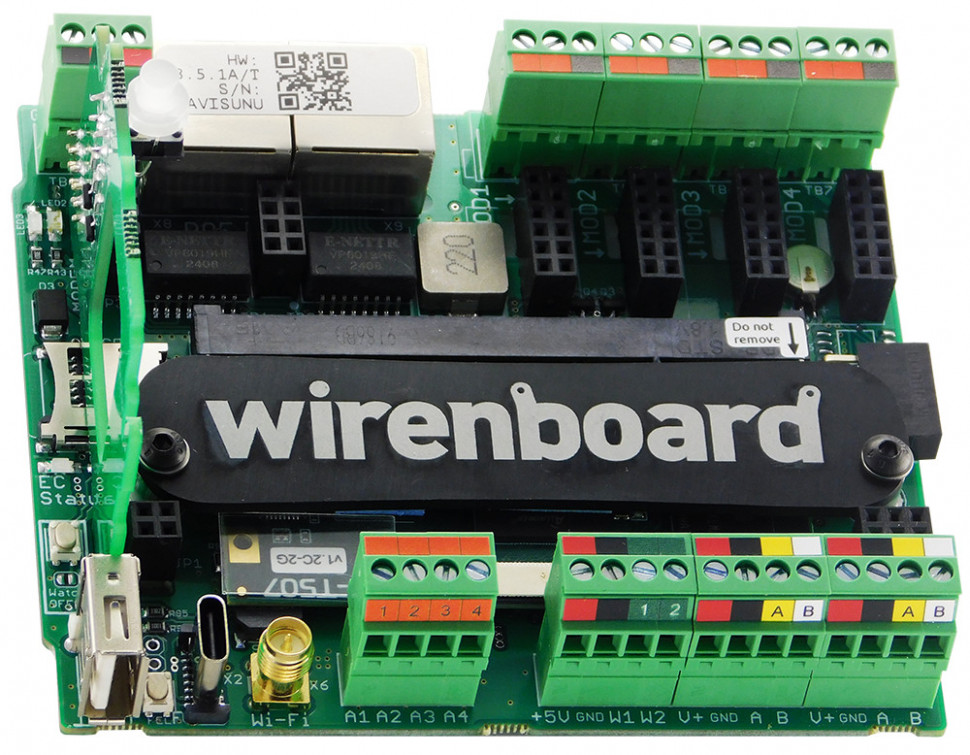

PLC Wiren Board 8

- FCA – you pick up from us

- DAP – we deliver, you do customs in your country and

- DDP – we deliver and we do customs clearance

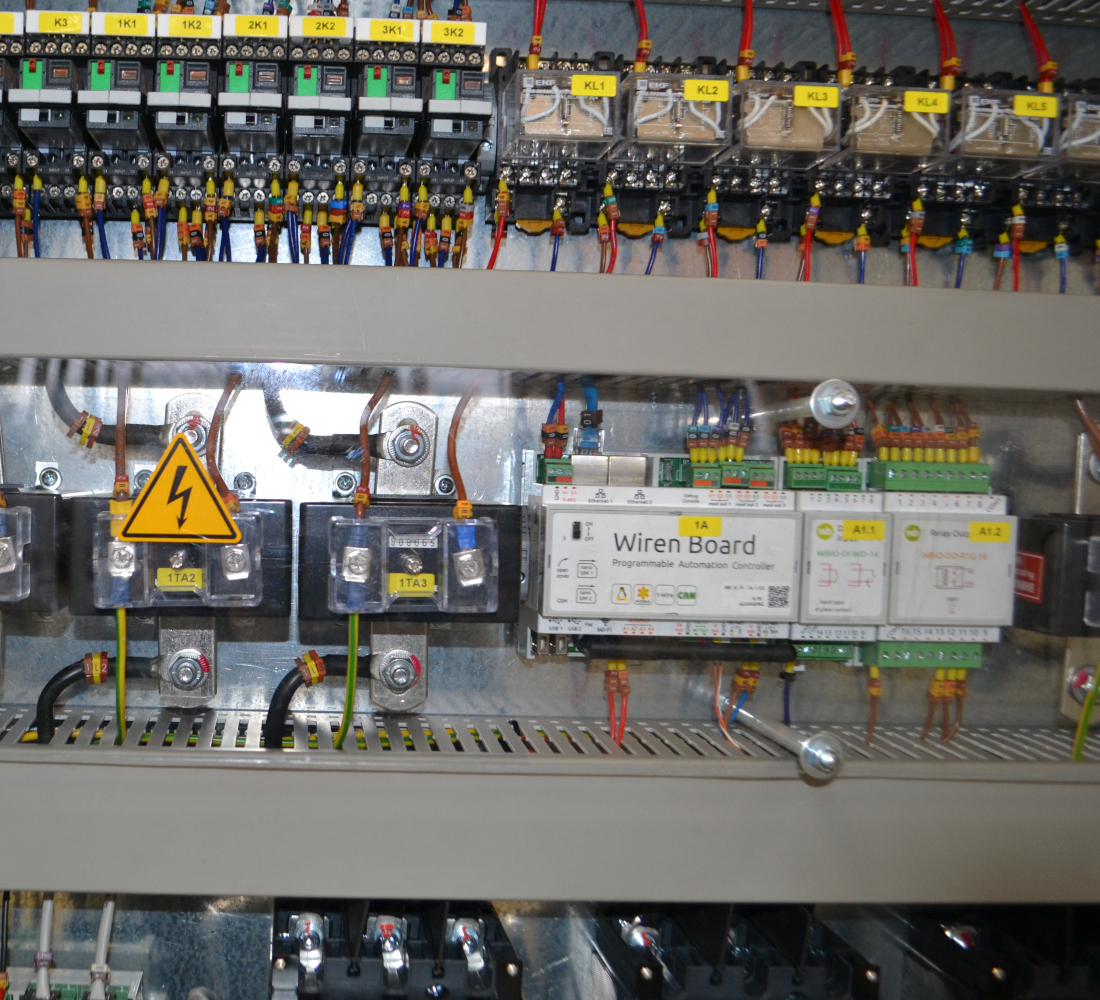

Wiren Board 8 is a PLC powered by free software.

Wiren Board PLC are used in the tasks of monitoring server and climate equipment, dispatching and collecting data from metering devices, as the basis for "smart home" and industrial automation.

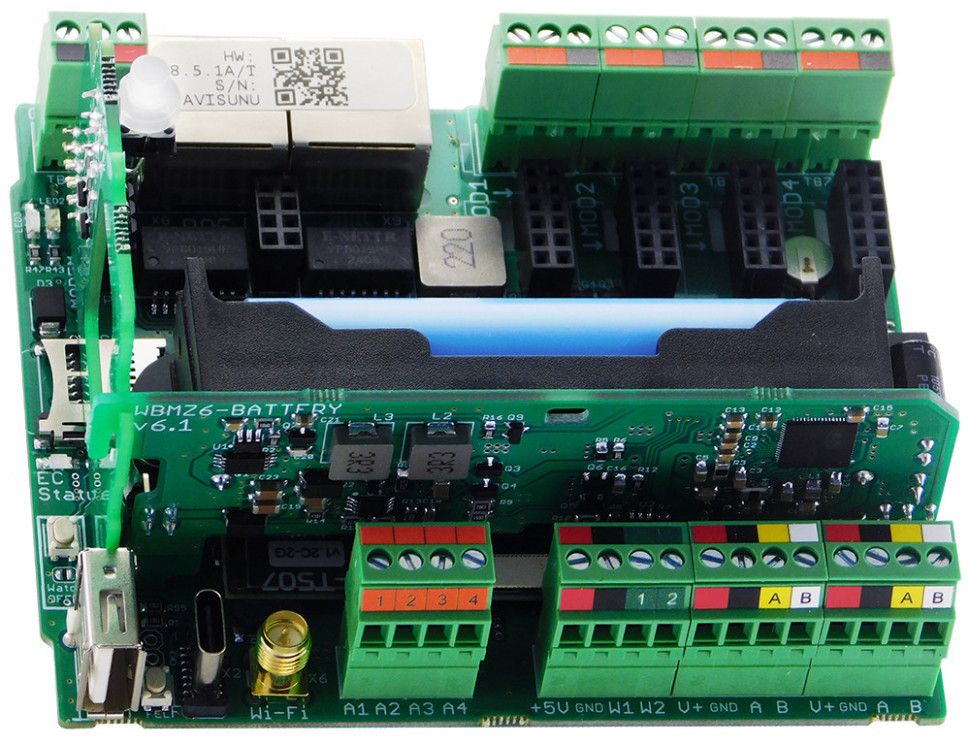

In Wiren Board 8.5, all four slots for MOD1...MOD4 modules have terminal block outputs and allow the installation of WBE2 and WBE2R expansion modules, the Debug Console and Debug Network functions are combined in a single USB-C connector, and the built-in heating of the processor board allows the controller to start and operate at temperatures from -40°C.

MAIN FEATURES

Hardware and software

Any configuration includes an industrial 4-core 64-bit ARM Cortex A53 processor with a frequency of 1.5 GHz, but the available RAM and permanent memory depend on the version:

- from −40 to +75 °C: up to 4 GB LPDDR4 RAM and up to 64 GB eMMC;

- from −40 to +75 °C: 1 GB LPDDR4 RAM and 8 GB eMMC.

The controller uses the open operating system Debian Linux 11, kernel 6.8, which provides ample opportunities to install third-party software. There is also hardware protected a key store that can be used to authorize the controller in its services or to link software licenses.

The built-in software is free, open and allows you to configure the controller and devices connected to it, write automation scripts, store and view archives measurements.

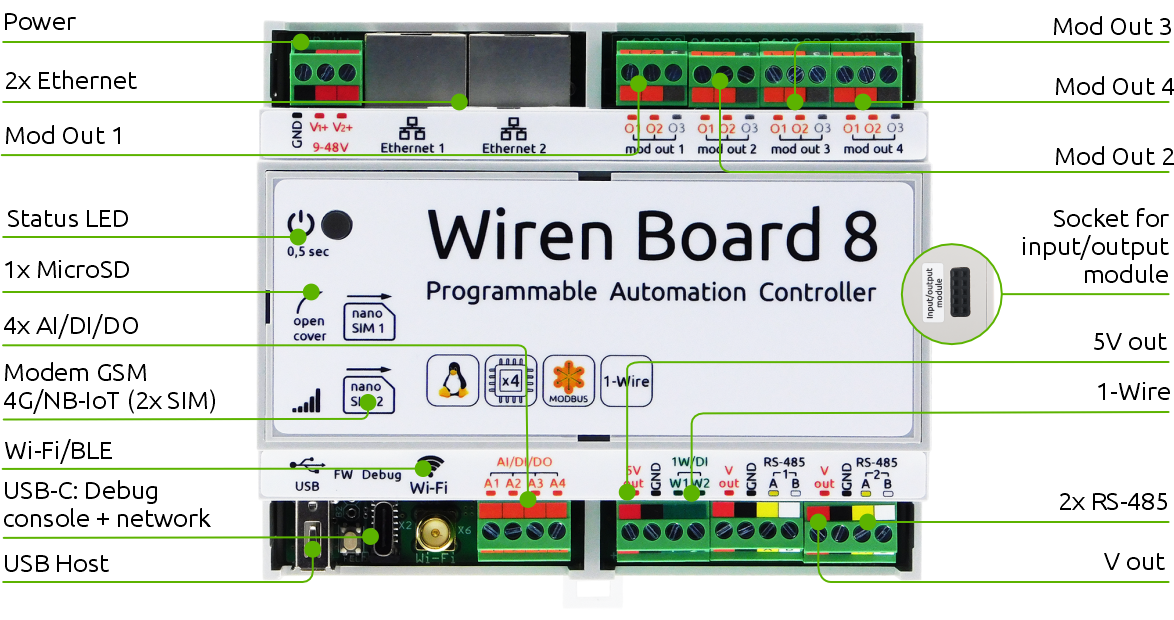

Interfaces and Communications

In the basic configuration of the controller:

- 1 × MicroSD slot, up to 60 MB/s

- 2 × Ethernet 10/100

- 1 x USB Host

- Wi-Fi 802.11n (AP, client), two bands 2.4 and 5 GHz

- Bluetooth 4.2 + BLE

- 2 × RS-485

- 2 × 1-Wire/digital inputs

- 4 × digital/analog open collector inputs/outputs

Additionally, using extension modules:

- 4G (LTE) modem for two SIM cards in nano SIM format

- Z-Wave and Zigbee

- PoE 802.3af, 802.3at or Passive PoE

- CAN and HDMI (in development, if needed, write to us)

Supported protocols

The controller supports a wide range of protocols and devices:

- Modbus RTU – relays, dimmers, I/O modules;

- Somfy, WINDECO, DOOYA, AKKO – electric curtains;

- IEC 61107, DLMS/COSEM – electricity meters;

- 1-Wire – temperature sensors like DS18B20;

- Wi-Fi, Bluetooth – sensors, gateways, and devices;

- Modbus TCP, MQTT, OPC UA, SNMP, Zabbix API – data exchange with other controllers, servers, and SCADA systems;

- IEC 60870-5-104 – protocol used in power systems and industrial SCADA integration;

- Danfoss, Carel, Eliwell – refrigeration controllers such as Danfoss EKC 202B/D, ERC 21x, and Carel BASIC/EASY;

- KNX – integration with existing KNX systems (with add-on modules);

- OpenTherm and eBUS – electric and gas boilers (with add-on modules);

- Z-Wave, Zigbee, DALI – sensors, actuators, and lighting devices (with add-on modules);

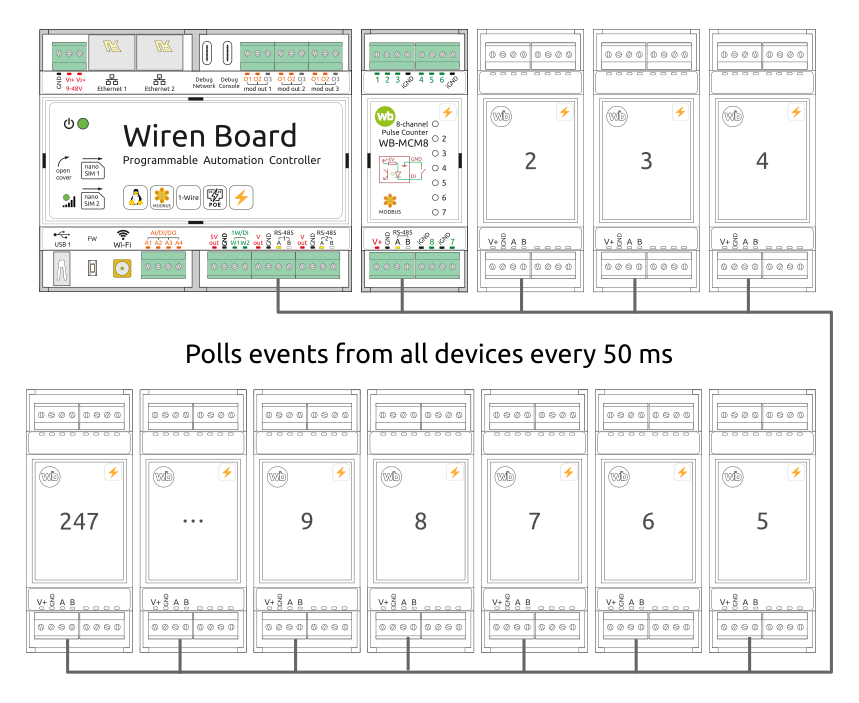

Fast Modbus support

All Wiren Board devices, in addition to the standard Modbus RTU, can work with its extension Fast Modbus ⚡, which adds new features:

- instant polling of input states and measured values via events;

- quick search for devices connected to the controller;

- resolving address collisions on the bus.

Additional features are enabled automatically - if the device supports extension, the controller driver will work with the device quickly Modbus if the device does not know anything about the extension - it will work using standard Modbus RTU.

Features

The controller can operate at air temperatures from -40 to +75 °C. It is often used in unheated outdoor panels.

Port overvoltage protection and a watchdog timer allow the controller to be used for solutions that require reliable operation.

The DIN rail housing and supply voltage range from 9 to 48 volts will help you integrate the controller into an existing automation panel or easily assemble a new one.

The open platform makes it possible to install third-party software or develop your own.

A wide range of external modules will help you build a fault-tolerant automation system for any task, and support for various data transfer protocols will help you integrate the controller into an existing one.

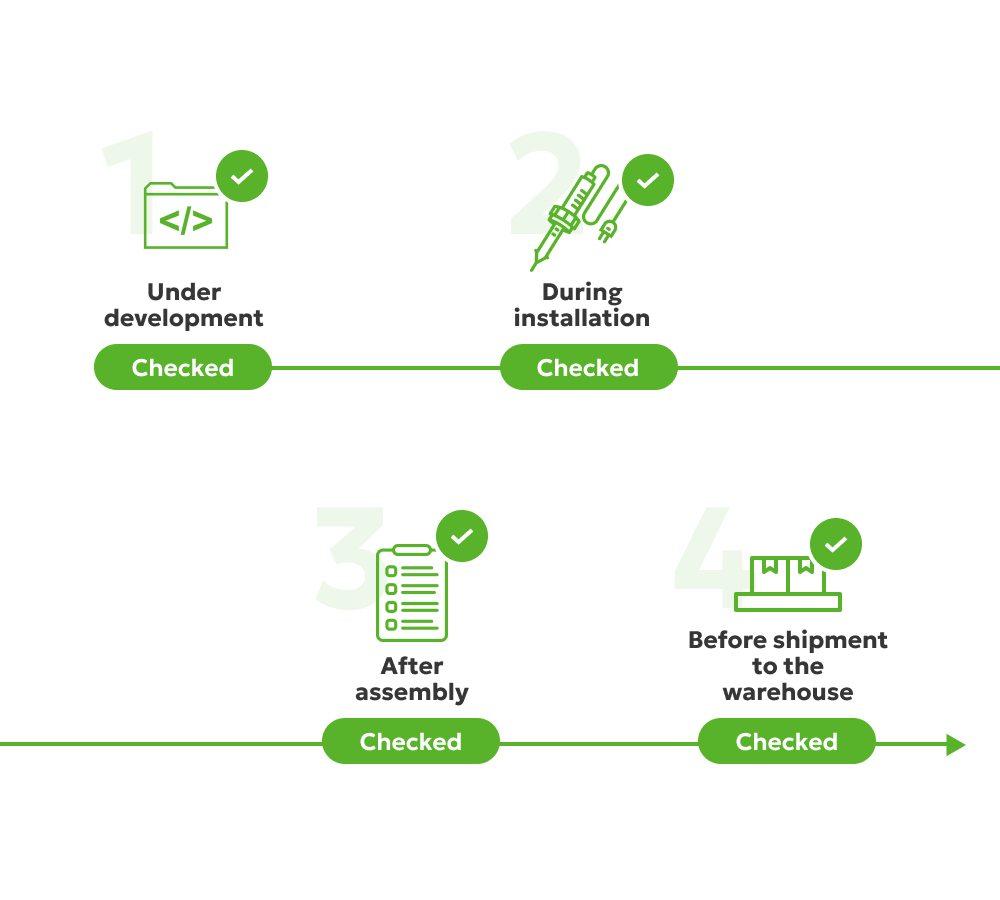

Quality control at every stage of production

We develop and manufacture all Wiren Board devices ourselves. Also everyone devices undergo multi-stage quality control:

- During development - checking the components used for compliance with the declared ones characteristics and testing of the prototype device at extreme operating conditions.

- After installation of SMD components - automated optical control.

- After soldering the lead components - visual inspection of soldering.

- After assembling the device, functional testing on an automated stand.

- When shipped to the warehouse - control of completeness, stickers, appearance.

Thanks to this approach, the failure rate is no more than 0.5% of all released devices.

If the device fails within two years from the date of purchase, we we will replace it for free without need to be sent to a service center.

Brand Wiren Board Weight 0.235 kg